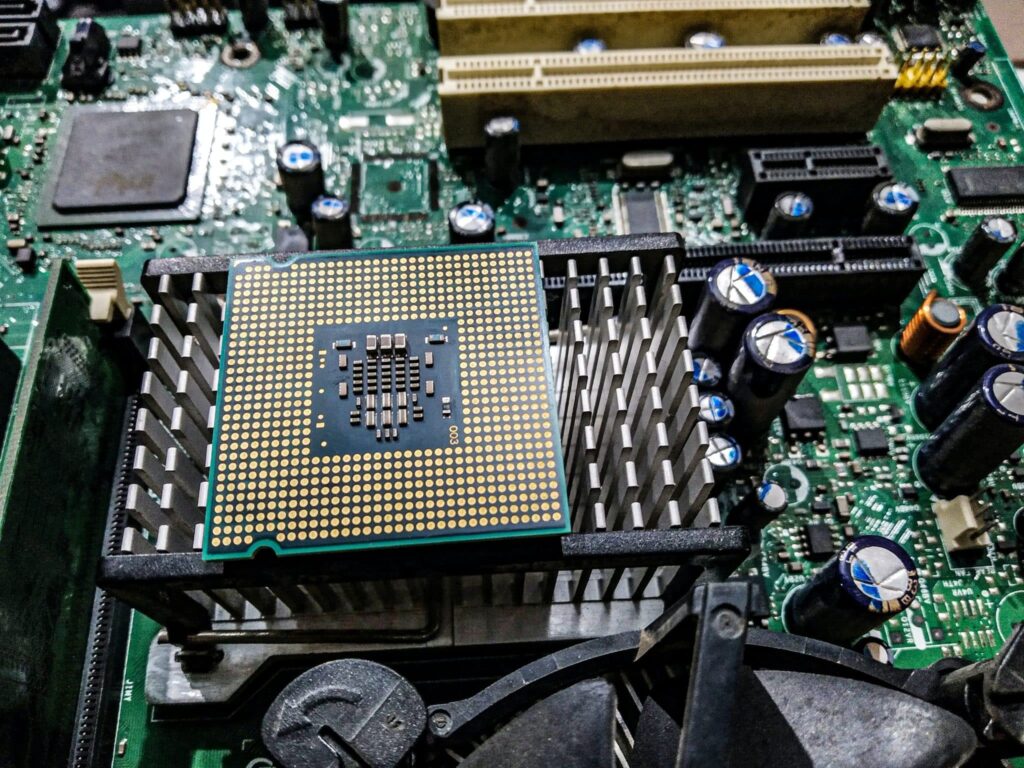

Soldering of a BGA

We currently produce a 24 layer board in China. The PCB has a solder mask dam of 80 µm and we can support even smaller solder mask dams. In general you always need to ensure the best soldering yield on your BGAs. For µBGA’s where the pitches equal to or is smaller than 0.5 mm, […]

Satellites

Add Your Heading Text Here A customer within Satellite and Communication, buys a 16-layer board in volume production (10,000 pcs) in China for around USD 10, -/pcs. We are informed of this target price and offer them a price of USD 5.36/pcs. In this collaboration, there is a mutual relationship of trust, which means that […]

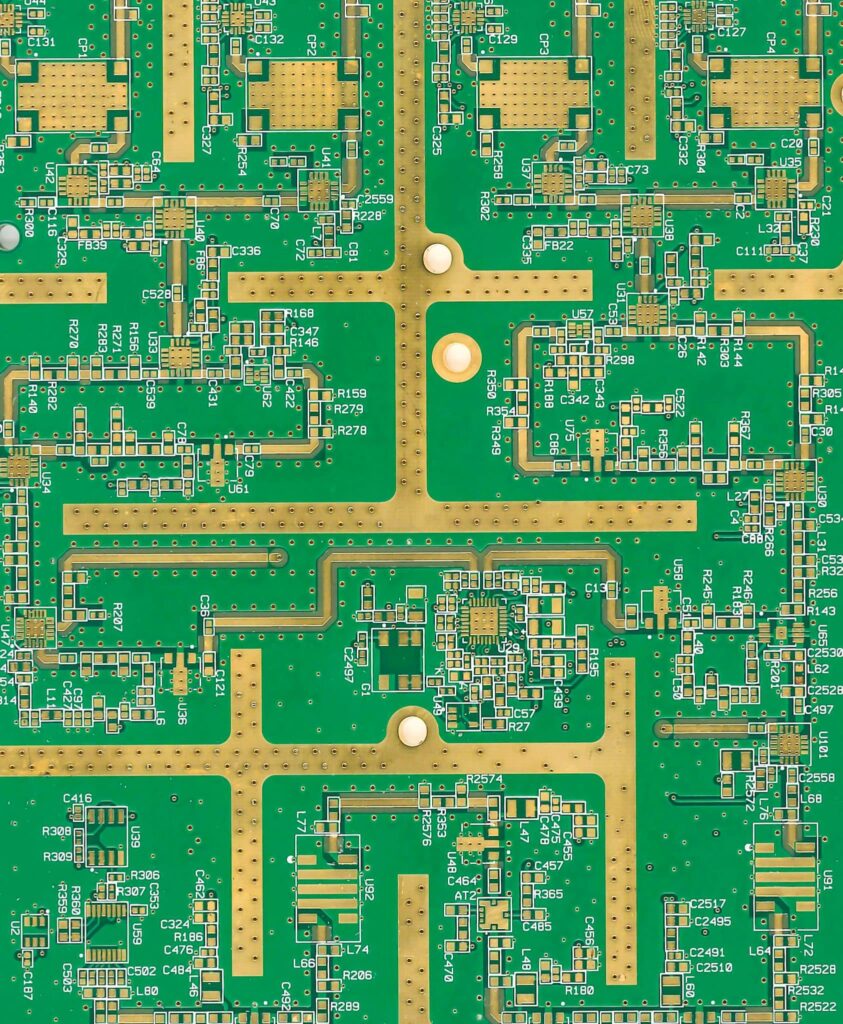

HDI Technology

A semiconductor customer in need of a prototype and volume production of 32 layers of stacked vias, had tried to produce the PCB with various partners in China. Azitech visited these PCB partners and would not have used them for this project due to their technology limits, which were too close to the print’s design […]

PCB Lamination

PCB Lamination When choosing PCB technology for your board, you should know that the PCB factory has different lamination options to meet your required PCB technology on your board. The lamination method used is based on your PCB type and in addition on the type of PCB technology you will apply to the PCB during […]

Fineline Width and line spacing

Chemical etching of a PCB is usually done with ammonium persulfate or ferric chloride. The thickness of standard copper sheets are typically 18 µm or 35 µm. Higher accuracy and fineline etching can be achieved by reducing the copper sheets thickness to 12, 9 or even 6 µm. Keep in mind that in most cases […]

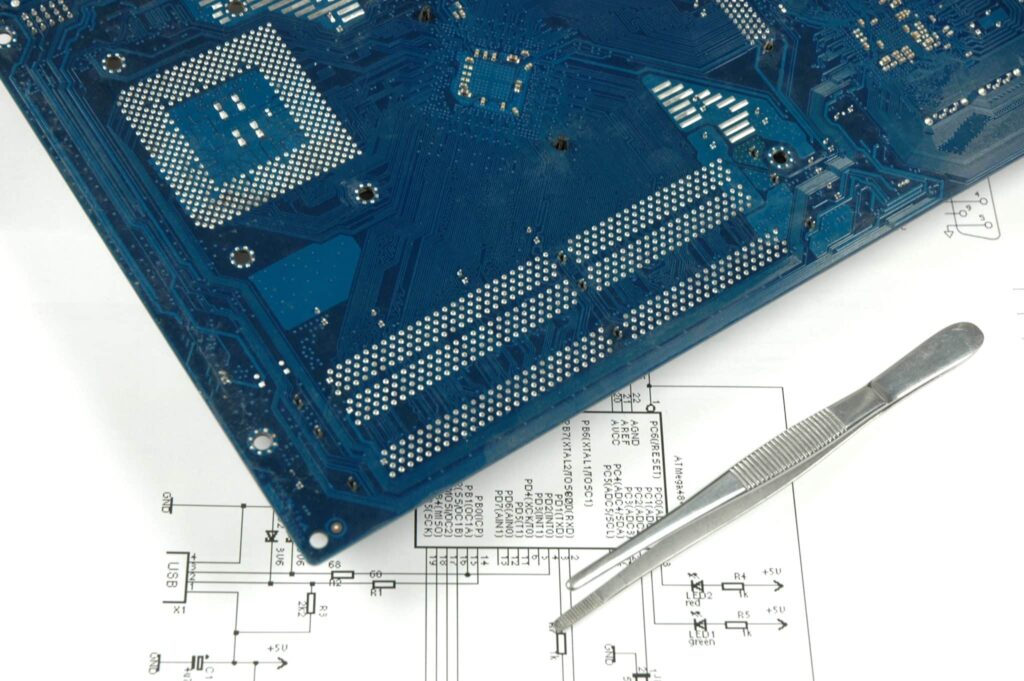

PCB Layout Guide

Designing your board is a very important and exciting stage in the PCB development. There are many limitations and requirements that need you need to remember when designing it. Making a mistake in the design phase will cause starting all over again and result in starting another production if it is not caugt in the […]

Surface finish for PCB by Azitech ApS

Choosing the correct PCB surface finish for your application requires taking factors into account like cost, the final application requirement like solder joint strength, high-heat, thermal, vibration, stability, RF, component density, single or multiple solder processes, shelf life, shock, drop resistance, production volume, and throughput. Selecting the right surface finish is therefore extremely important to […]